Pressure Gauge Reads but Resets to 0

The analog force per unit area gauge is ane of the simplest, mostly used instruments, and the easiest to calibrate in pressure level calibration. It has a simple setup where you can hands execute the calibration. Merely analog force per unit area gauge is likewise one of the instruments where errors are by and large encountered.

Most errors are either "out of tolerance" or the needle is not in the "zero settings". The post-obit are the commonly encountered issues with the analog pressure level gauge:

1. pressure guess needle stuck;

ii. pressure level gauge not zeroing;

three. the pressure reading is very far or out of calibration;

4. the worst, pressure approximate non working at all

When this happens, do not immediately throw or discard the gauges. Luckily, there are still ways to adjust or repair pressure gauges.

In this post, I volition share with you the post-obit:

1. 5 ways on how to adjust a pressure level gauge

2. The things to consider before making an adjustment or repair

3. how to identify the error in pressure guess and execute the adjustment.

4. How to verify a force per unit area judge.

5. Some useful tools to use to perform adjustments

Pressure gauges have different applications and therefore have too many construction designs.

I will nowadays in this post the different setups for unlike models of gauges to be adjusted.

Beneath are some reasons why pressure gauges are getting out of whack (out of tolerance or not in the null settings):

- Changes in the altitude and temperature (due to changes in environmental factors).

- Overstressed bourdon tube due to exposure to overpressure.

- Overused or overexposed to pressure cycle

- Exposure to high temperatures and excessive vibrations

- Wear in the mechanical parts.

The Things to Consider Earlier Performing Pressure Gauge Aligning or Repair

Pressure gauge errors tin can be identified during the execution of calibrations where we compare the readings of the pressure gauge confronting the reference standard or pressure level calibrator.

Pressure guess errors tin be calculated using the formula:

ERROR = UUT Reading – Reference Standard Reading

If the identified error is non acceptable or too large based on verification, then an adjustment is necessary.

During the pressure level gauge calibration procedure and we discover beneath defects, chances are high that aligning or repair is not possible.

- A reading near its full-scale value is shifted to more than than 10% (a span shift)

- Force per unit area gauges that take a zero shifted to more than than 25 % (a zippo shift)

- Gauges with signs of leakage and corrosion of its trunk.

- Gauges with a needle showing an error due to excessive friction or wear on its move (loose)

- With damage sockets and threads.

When the above signs are observed, in that location is a high chance that replacement is the simply option.

You tin read more in this article from ASHCROFT

5 Techniques to Adjust or Repair a Pressure Gauge

- Opening a vent to release pressure build-upward

- Opening the Glass (or plastic encompass) and so removing the needle.

- Rotating the screw located at the face up of the calibration.

- Adjusting the knob at the lower side of the force per unit area estimate

- Adjusting the screw located at the gauge needle pointer itself.

Be reminded that the above techniques are dependent on the construction or design of the pressure gauges .

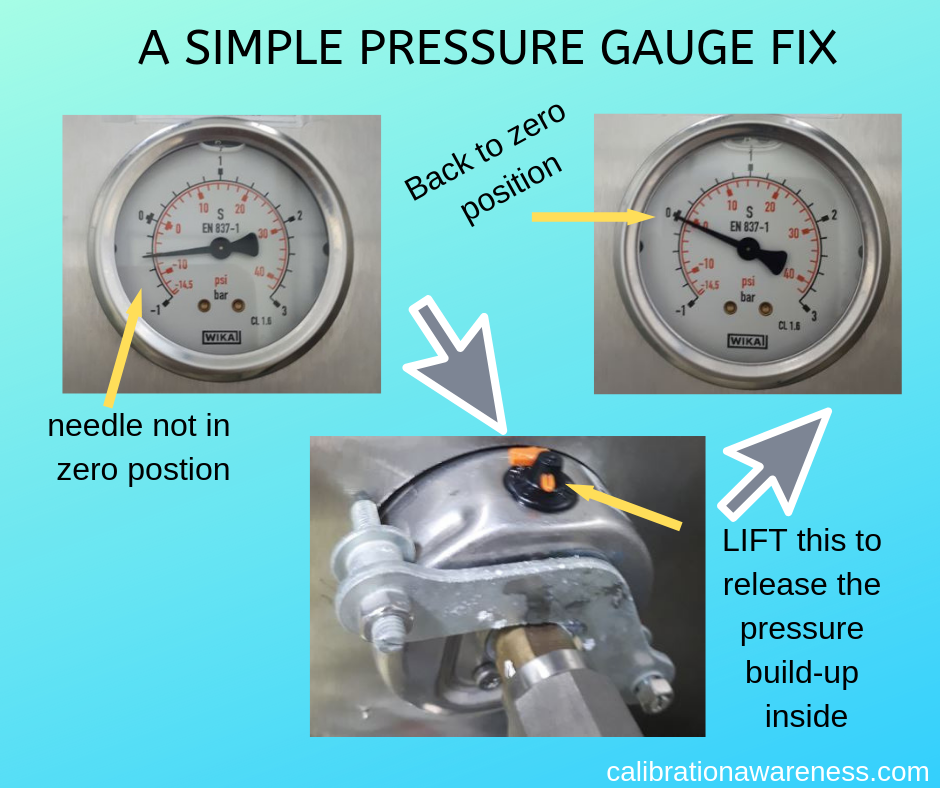

1. Opening a vent to release pressure build-up

This is the simplest technique. Due to changes in temperature and altitude, a pressure within the pressure guess will build-up and affect the needle settings to zippo. You can correct this past just opening the vent to release the force per unit area.

Do non forget to return or re-seal the vent. The oil may leak and may damage the guess.

This is the simplest of all the adjustment techniques that is usually applicable to most oil-filled and permanently sealed type of analog pressure gauge. If this technique does non fix the problem, so a replacement is the only fix. Cheque out replacement gauge here >> Force per unit area Gauges

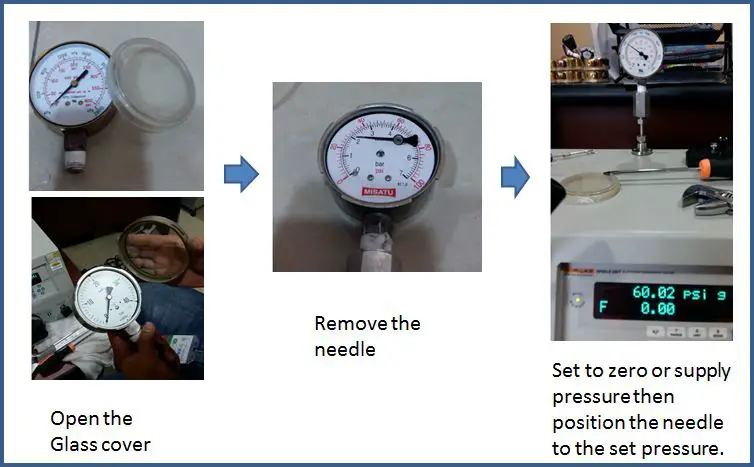

2. Opening the Force per unit area Approximate Protective Glass (or plastic comprehend) then removing the needle.

For a non-oil filled gauges and it is not permanently sealed (nearly oil-filled gauges are permanently sealed where adjustment or repair is not possible).

Simply in some cases where it tin can be opened, remove first the oil within before removing the glass cover. Yous need an actress oil replacement merely in case.

If yous are wondering what is the liquid filled within the pressure guess is, it is called glycerine or silicone oil. It is important to supersede or refill the pressure judge oil when removed or if the oil has been drained because of a leak.

What are the advantages of oil filled pressure estimate? Below are some of the reasons why we need to maintain the oil-filled force per unit area estimate:

- Oil filled pressure gauges are more protected from harsh ecology factors and moisture or water condensations. Some pressure judge mechanical parts go stuck from dust and corrosion build-upwards resulting in wrong readings, or worst, damage.

- Glycerine Oil-filled force per unit area gauges are also protected from potent vibrations. Strong vibrations have an effect on the mechanical components. Some needles are getting removed or broken because of these potent vibrations.

- Since the liquid-filled force per unit area gauge can resist strong vibration, the displayed readings of the needle are more than stable, making it easy to read, thus, increasing the accuracy of the pressure gauge.

- Glycerine or silicone oil acts every bit a lubricant for the mechanical parts especially for the needle pointer making it move smoothly.

(encounter at the lesser of the page the tool to remove the cover and needle hands and safely).

In some cases were releasing the force per unit area build-upwards cannot solve the problem, nosotros can perform below adjustment by opening the force per unit area approximate through the removal of its protective cover and removing the needle pointer. With this method, we can correct the zero and span shift of the instrument when it occurs.

A. To correct the Zero Shifts:

Once the cover is removed, perform below steps:

one. Pull the needle using the needle puller (see below).

2. Once the needle is removed, position information technology on the zero scales and then button to return.

3. Verify the reading by supplying pressure

How to perform pressure gauge verification? Read on …

B. To correct Span Shift:

Once the needle is removed, perform the following:

1. connect the pressure gauge to a known pressure source (the Electronic Deadweight Tester or Fluke 754 with a set of pressure modules)

ii. Generate a force per unit area of most 50% of its Full scale. Once the pressure is fix, return the needle on the same value as the supplied pressure. For example, generate a 100 psi pressure from the reference standard, then set up the needle on the 100 psi scale reading on the force per unit area gauge.

3. Perform verification to ensure that information technology is now inside the accustomed range.

Virtually of the time, Just performing either A or B solves the problem.

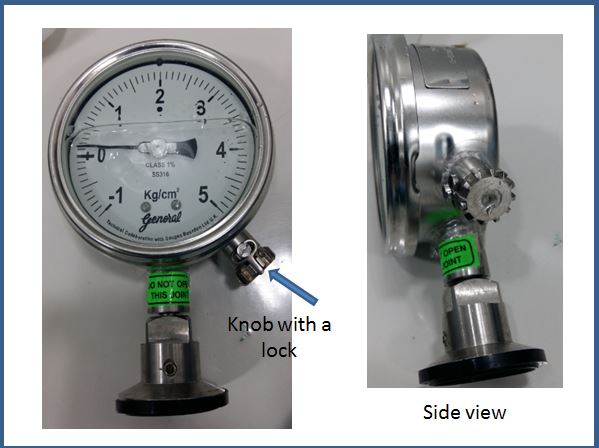

3. Adjusting the knob at the lower side of the pressure gauge

Some pressure gauges have an adaptable knob in the lower side of the body. This is a diaphragm-type pressure gauge that is usually used in h2o treatment pipings.

Only remove the lock and so the knob volition freely turn to adjust the needle.

iv. Adjusting the spiral located inside the pressure gauge machinery

Some pressure gauges have an adjustable screw inside the body, at the back of the needle or within the dial face. This blazon of gauges is used in gas lines.

Access the screw inside the approximate past removing the comprehend. Turn the screw either clockwise or counterclockwise to return the needle to null position.

Perform verification after zeroing.

.

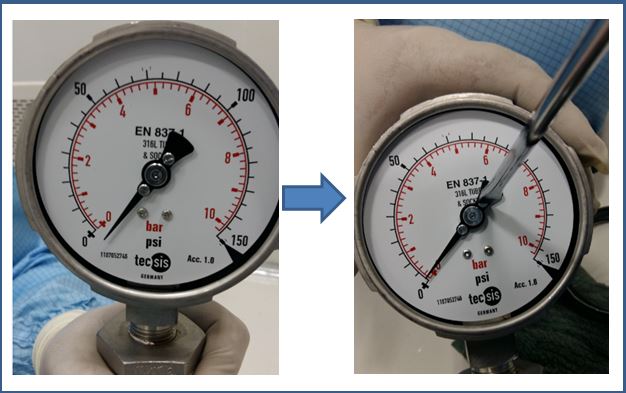

v. Adjusting the screw located at the guess needle arrow

This applies to some pressure level gauge that has an adjustable spiral integrated on the needle itself. Once the cover is removed, use a screwdriver and carefully plough the spiral to position the needle. See the figure higher up or watch the video below.

Based on the photograph in a higher place, I have shown you the location of the screw and the position for the screwdriver, but during rotating of the screw, you need to concord the needle to rotate the screw and perform the aligning.

You need to be more careful in this type of adjustment. the needle is continued with the spring inside and it is very sensitive. A strong force during rotating the screw can damage the whole function or force per unit area gauge.

After performing the adjustments, do not forget to verify the pressure gauge.

How to Verify the Accuracy of Pressure level Gauge After Aligning?

In every adjustment or calibration that we performed, nosotros need to verify if the readings are within the pressure gauge acceptable range, tolerance or acceptance criteria.

Earlier performing the adjustments, information technology is important that y'all should consider what tolerance you should follow.

The tolerance or acceptance criteria is based on:

1. manufacturer specification;

2. user or process tolerance.

3. International Standards or Regulatory requirements ( ex: ASTM or ISO Standards)

As an example, we volition exist using the manufacturer specs to verify the pressure level gauge. Below are the steps:

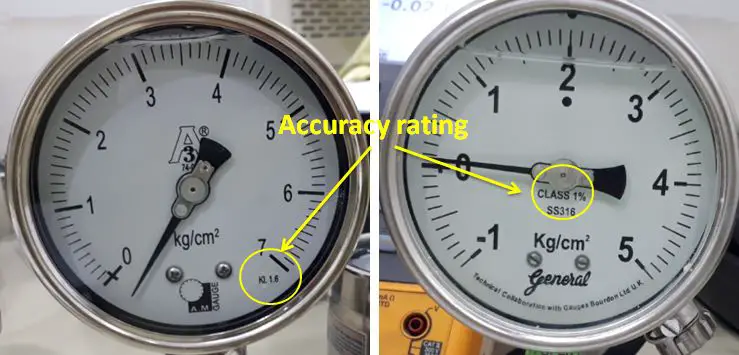

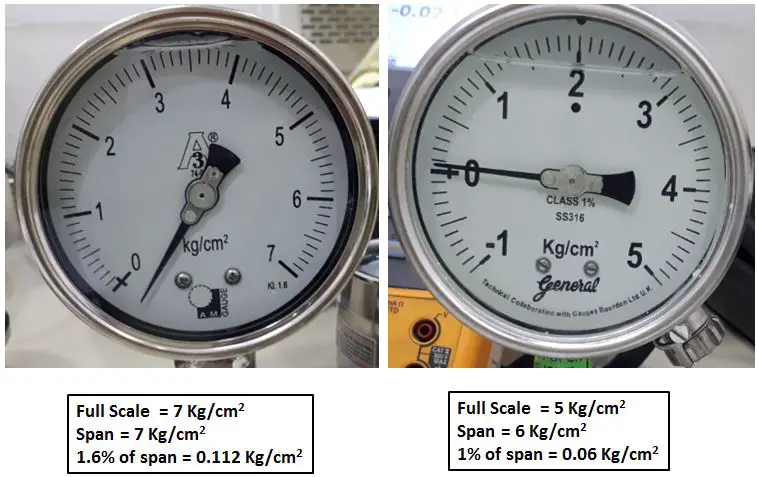

one. Make up one's mind the accuracy rating (accuracy class) of the pressure gauge. Most pressure gauges have the accuracy grade printed in their punch face (see below photo). This accurateness course has an equivalent MPE (Maximum Permissible Fault) where we can summate the limits of permissible error.

Learn more well-nigh the relationship and differences of accurateness, error, tolerance, and dubiousness in my other mail service on this link>> accuracy-mistake-tolerance-uncertainty

two. Convert the accurateness course to decimal past dividing information technology by 100 and so multiply it with the Span or FS reading. This rating is in percent of Total Calibration or Bridge. Based on the photo above, the force per unit area judge is labeled with KL 1.six which means 1.half-dozen% of Total Scale and Course 1% equivalent to 1% of Span (see example below).

The difference Between Full Scale and Span in Pressure Gauge Display

The difference between Bridge and Total-Scale reading

Full Scale (FS) reading is equivalent to the maximum displayed value of the force per unit area estimate. Information technology is from Zero to maximum range.

Span is the deviation between the lower range (not Zero-value) and higher range. Span range is applicable to those force per unit area guess with a negative value (see photo in a higher place-right side gauge).

Bridge = v – (-1) = 6

Span and Full-Scale reading are the aforementioned when the lower range is equal to Naught.

To determine the tolerance limit, we will multiply the accuracy grade rating with the span or FS reading. Run across the example beneath.

- The force per unit area gauge has an accurateness of 1.half-dozen% of Full-Calibration (FS)

- Full-Scale reading is = seven Bar

tolerance limit = (one.6/100) x 7 = 0.112 Bar

- Therefore, reading should be within +/- 0.112 Bar

three. One time the tolerance limits or the acceptance criteria are determined, generate the necessary pressure requirement so compare readings. If the reading is outside of this range, then more than adjustments are needed.

If you have performed ane or all of the adjustments above and withal the pressure gauge is out of tolerance, then it is already damaged and replacement or a deeper repair is the only option.

Some Useful Tools During Adjustment

- Hand Jack Fix Gauge Needle Puller. Yous can use this tool to remove the needle safely and effectively:

Click hither to check at Amazon

In removing the needle, be careful not to pull the needle so hard to avert damaging the pinion mechanism. Some needles are very tight where you can pull the pinion with it. In order to avoid this, you may utilise this tool.

ii. Strap Wrench Set. Apply this tool to remove the glass cover safely and easily.

Conclusion

In this article, I have shared the following:

1. 5 ways on how to adjust a pressure gauge,

2. The things to consider earlier making an aligning or repair

3. how to identify the mistake in pressure approximate and execute the adjustment.

four. How to verify a pressure judge.

five. Some useful tools to utilize to perform adjustments

Y'all can salvage and re-utilise a pressure gauge by performing regular calibration and adjustment, post-obit or choosing the right setup suited for a specific pressure gauge as explained in this article.

If you have other methods to arrange or repair a pressure gauge, delight do non hesitate to comment.

To acquire how to calibrate a pressure gauge, visit this mail service: force per unit area-gauge-scale-using-fluke-754-process-calibrator-with-a-set up-of-fluke-pressure level-modules

Give thanks you lot for visiting my site.

Please comment and subscribe.

You can as well connect with me in my Facebook page.

Deeply appreciated if you lot purchase me a scale mug.

Best Regards,

Edwin

Source: https://calibrationawareness.com/5-techniques-pressure-gauge-adjustment-repair

0 Response to "Pressure Gauge Reads but Resets to 0"

Post a Comment